Case: Norditech – LabelDetector, AI streamlines warehouse management

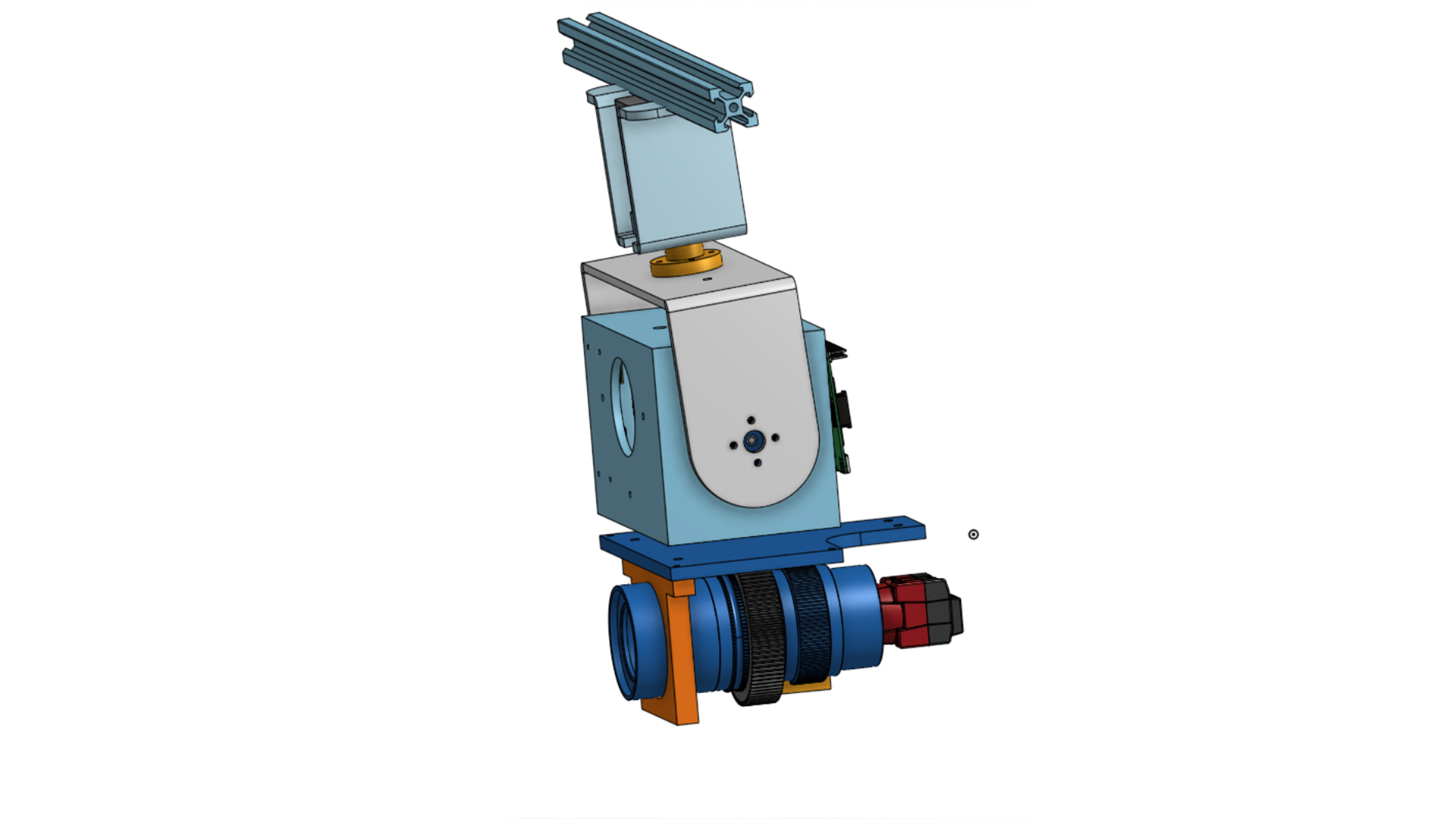

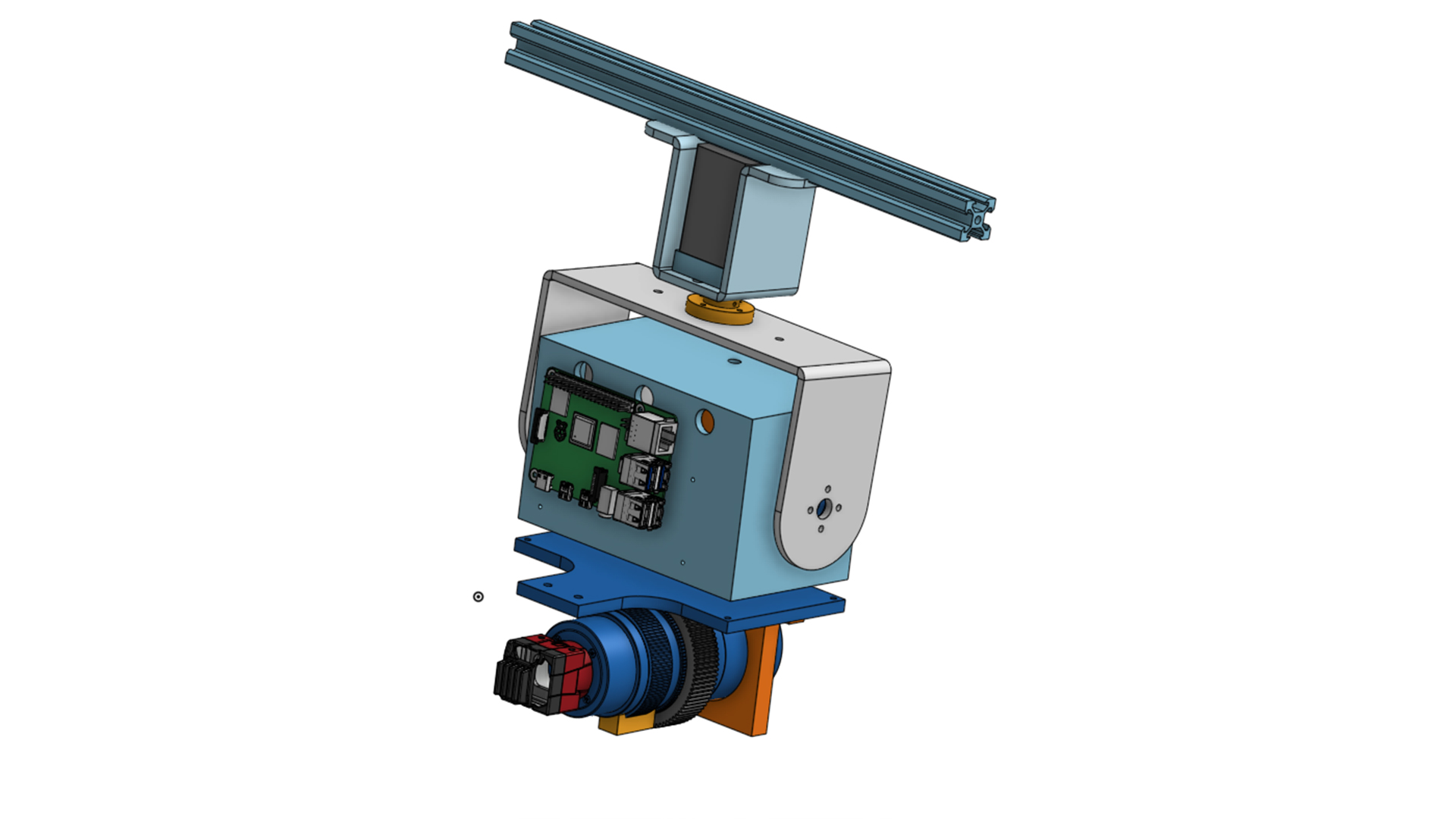

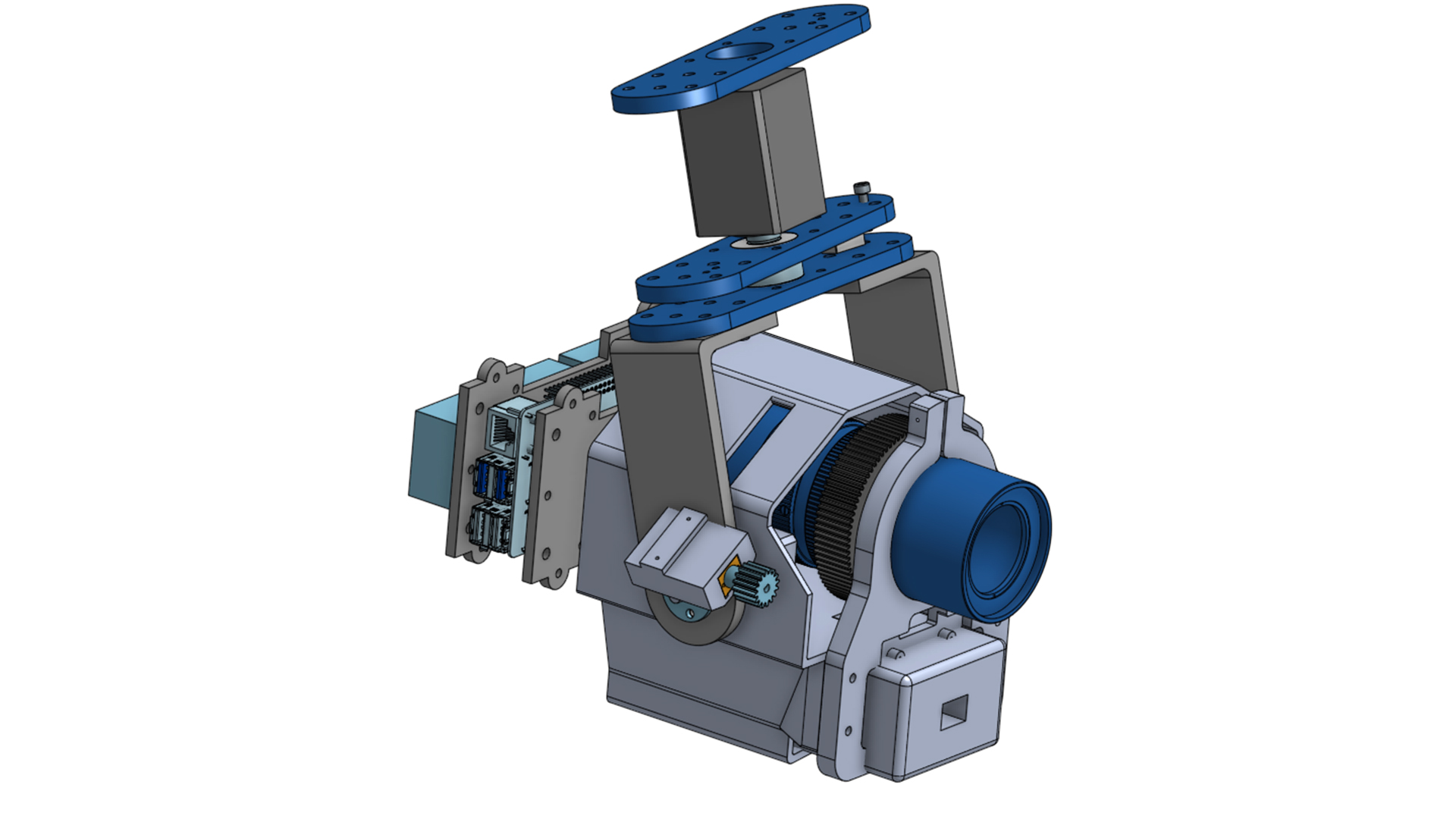

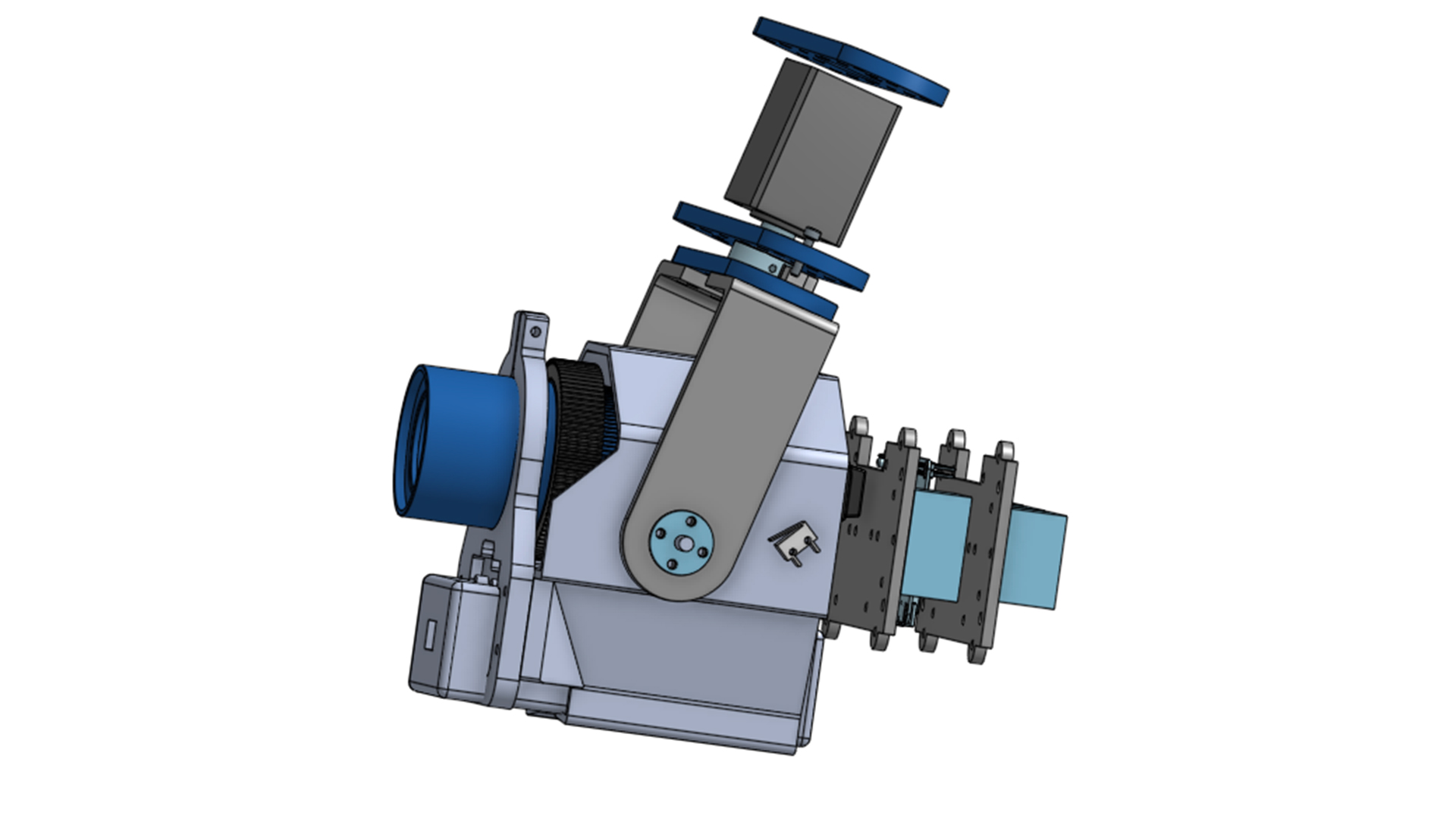

LabelDetector is an add-on to existing warehouse systems that gives companies more information about products and flows in their warehouses. Using a smart camera system with AI, LabelDetector continuously collects information from the warehouse that is processed and used in various ways to streamline and develop inventory management, for example:

- Searching for products

- Remote overview

- Tracking of products

- Automatic inventory and accounting

- Warehouse optimisation and process improvement

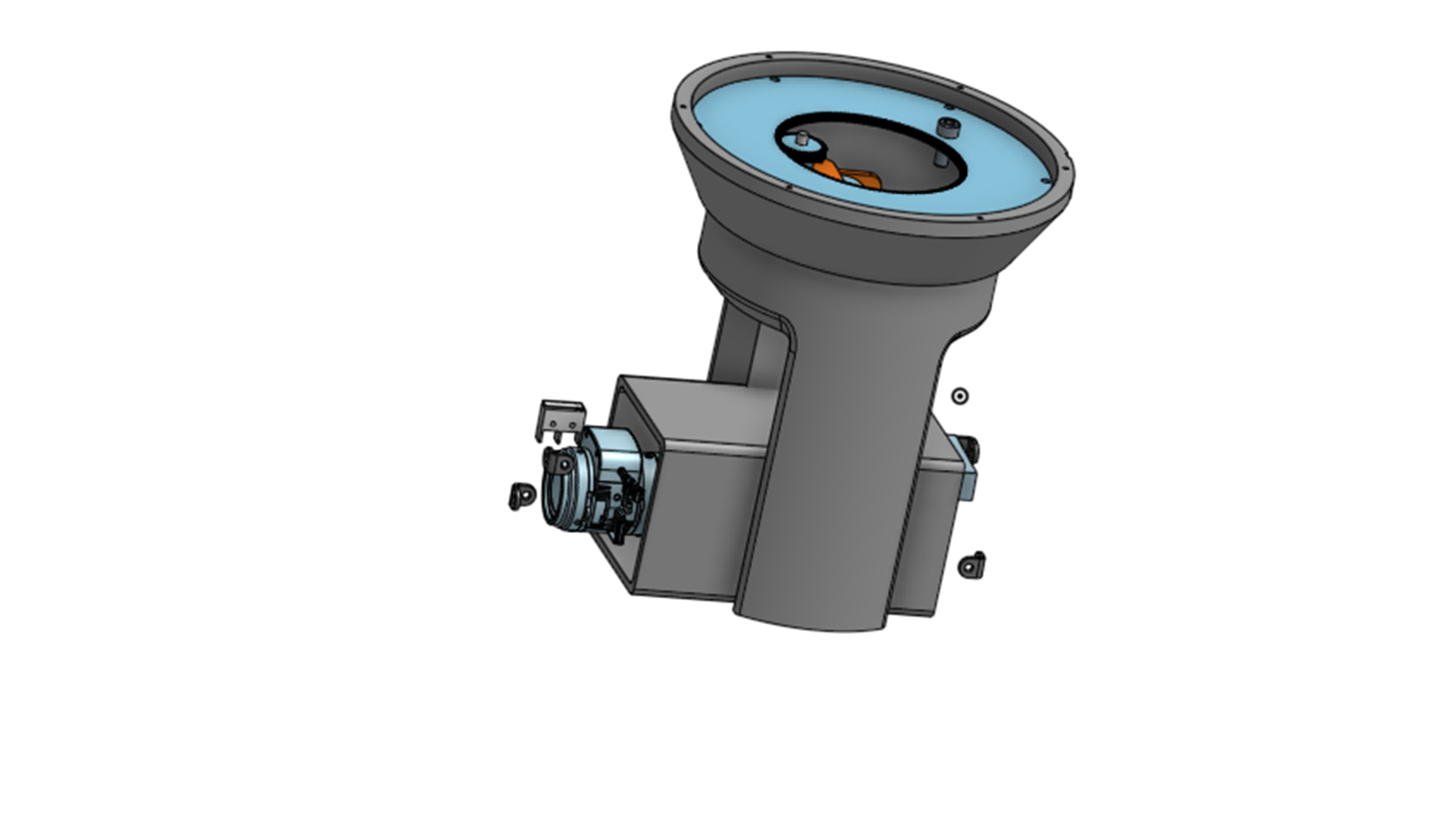

The technology can be implemented without having to change the company's current process, nor does it require any customised shelving or labels, making it easy and cost-effective to get started. An installation is often up and running in less than 24 hours. The only physical items that need to be installed are cameras. A demonstration can be done during a customer visit in about 1 hour.

Today, many companies spend a lot of manual time in their warehouses taking inventory, keeping track of their products and posting against their ERP systems. "It is not uncommon for a company, with ten employees, to spend over 3000 hours just on inventory - every year", says Philip Alm, co-founder of Norditech.

With LabelDetector, advanced AI technology and camera systems are used to find labels, read them and match them against business systems fully automatically. LabelDetector integrates directly with companies' existing processes and systems and does not require any new off-the-shelf software, labels or shelves to get up and running. This makes it very easy and cost-effective to implement, opening up the possibility for many more companies to streamline their warehouse management using new technology.

LabelDetector helps companies to automatically control stock inventory and post transactions directly to the business system in use (such as Monitor). The solution also provides remote visibility and the ability to track products. With the information collected by the system, Norditech aims to help companies move towards more sustainable solutions by optimising workflows and environmentally tracking warehouse products. Using statistics-driven tools, it would be possible to follow the entire product lifecycle and optimise everything from waste to CO2 emissions.

Read more here.