Third time the charm: Elmia Subcontractor is important to us

- We were here four years ago as visitors, and that´s when we decided to become exhibitors too. We had been looking for a good trade fair and concluded that this is the very best trade fair for subcontractors, says Mirnes Kahrimanovic, CEO of My Components.

The joint stand from Bosnia and Herzegovina also speaks for itself:

- Six companies in the same stand. We work sustainably even when it comes to trade fairs, says Senad Mehmedagic with a smile.

“More and more are turning to Bosnia”

My Components has six employees and has been in business for five years. As an export-dependent injection moulding company, it has chosen to focus on the furniture industry and telecoms in Scandinavia and the rest of Europe as its primary market.

- And we are noticing that more and more people are turning to Bosnia to find subcontractors, especially after the challenges of recent years in the global supply chain. We are geographically close and we are not part of the EU, we have lower wage levels in industry, which in turn can secure a better price structure for our customers, says Senad.

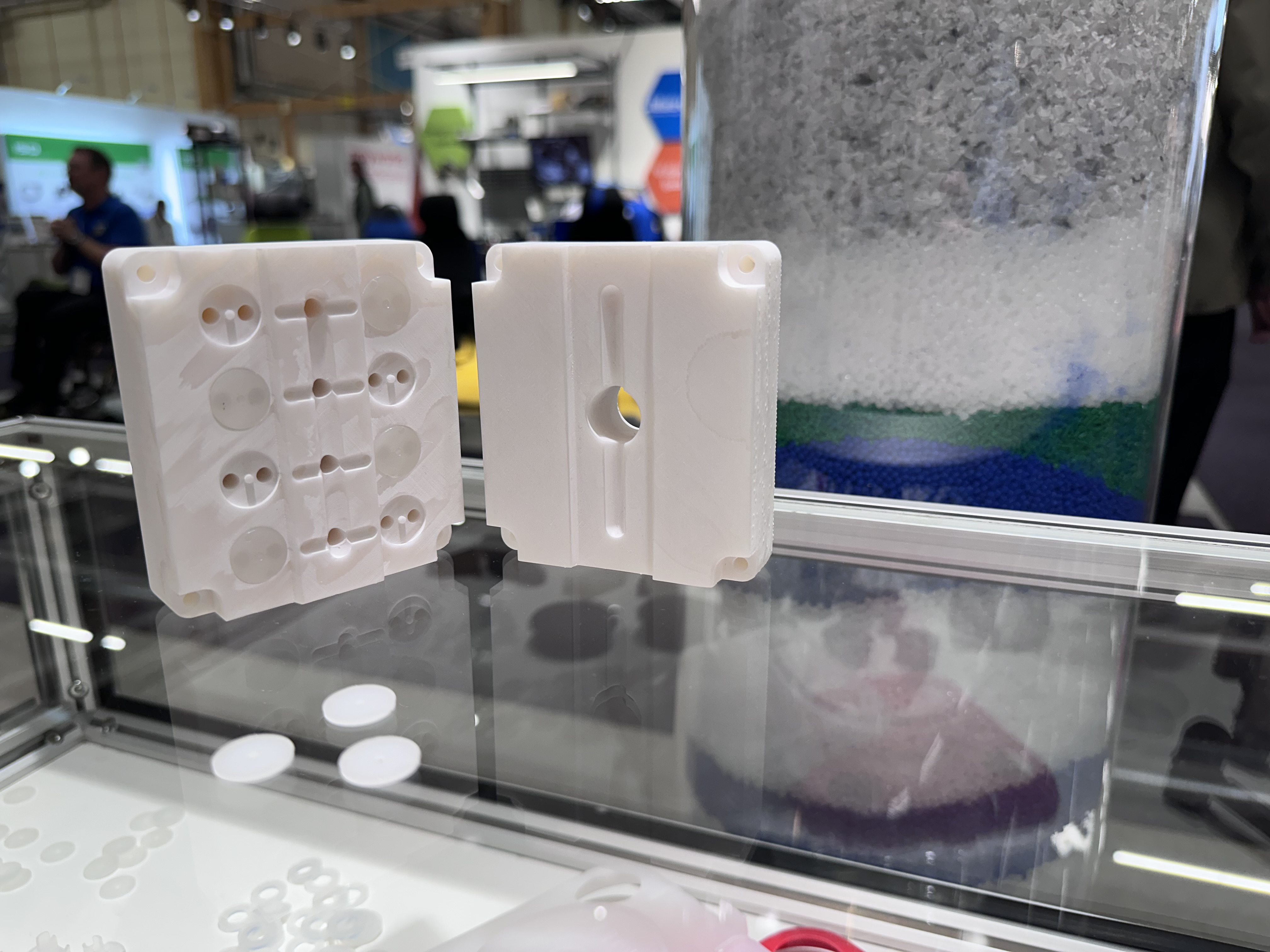

3D-printed tool inserts are an innovative way to lower the financial threshold for trial series.

Prioritises fast deliveries

Not belonging to the EU has both advantages and disadvantages:

- We have trade agreements with the EU, which means you don't have to pay customs fees, but we often have slightly longer border controls. However, we compensate for this with early loading for just-in-time deliveries, explains Mirnes.

My Components works hard on its transport operations, with lorries travelling north continuously every week.

- We load the goods at our premises on Friday and our customers receive them on Tuesday, or Wednesday at the latest, says Mirnes.

3D-printed tools reduce costs

The ability to produce using recycled materials, ISO 14001 and 9001 certification, FSC certification for packaging and materials that meet REACH requirements are a given if you want to be a supplier in plastic injection moulding today. But My Components is also at the forefront when it comes to new innovative ways of producing.

- We work with 3D printing for both prototypes and tool manufacturing. With 3D-printed inserts, we can cut the costs of test tools and test series to a third, says Mirnes Kahrimanovic.